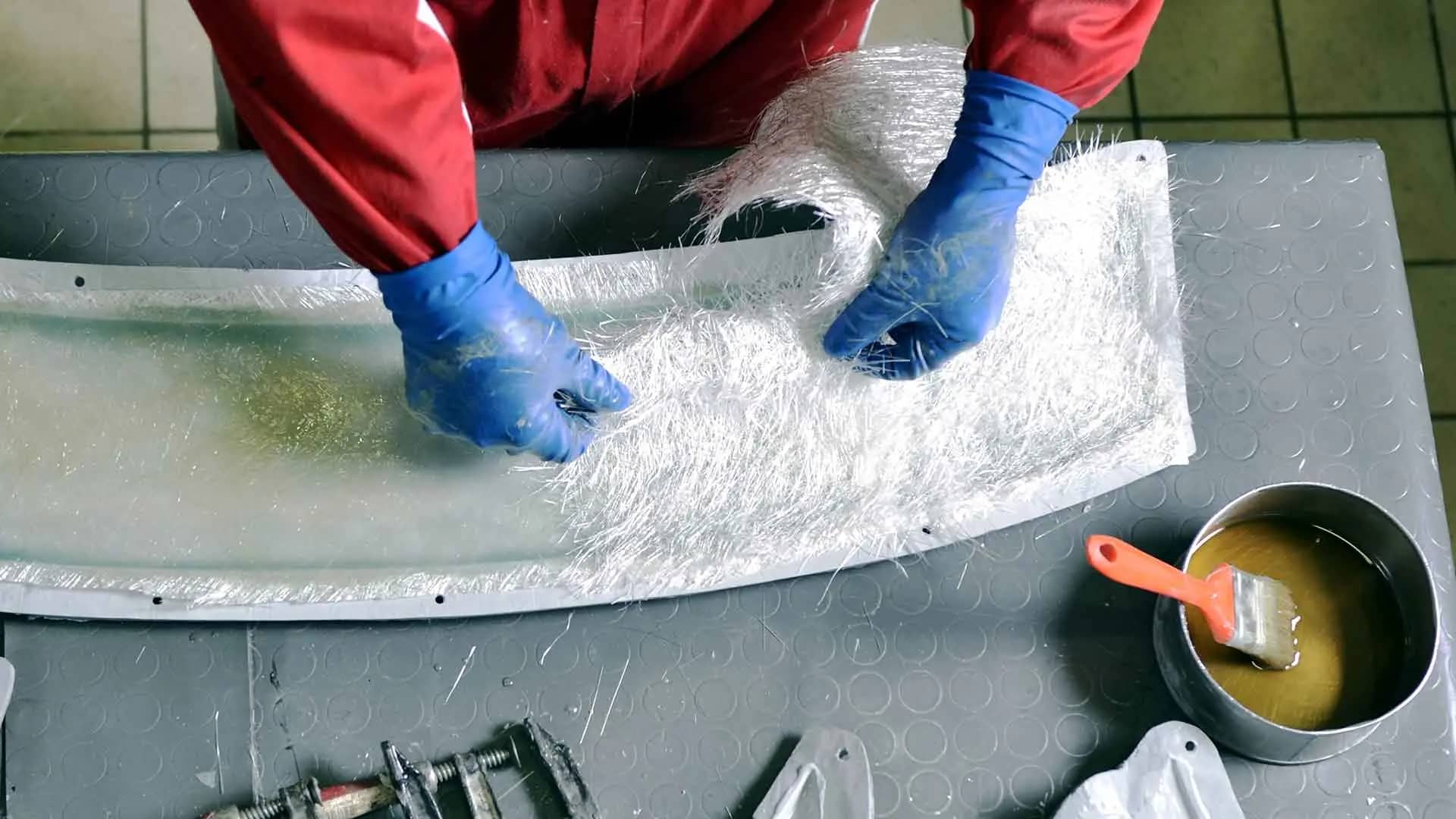

Principal Properties & Application:

ALITA 901-1 is a high-performance epoxy vinyl ester resin specifically designed for fast pultrusion applications, especially for manufacturing high-quality FRP optical cable strength members and FRP rods with diameters from 0.5 mm to 4 mm.

- Enhanced Surface Finish: Improved surface gloss of pultruded products.

- Dimensional Stability: Reduced shrinkage and internal microphase cracks.

- Superior Mechanical Properties: High heat-resistant bending and strength in the final FRP core material. A core material circle with 50 times the diameter of the FRP core material can withstand 24 hours at 100°C without breaking, minimizing defects in high-end core materials.

- Excellent Durability: The pultruded products exhibit outstanding corrosion resistance, mechanical properties, and electrical properties, making them ideal for demanding applications.

Liquid resin technical indicators:

| Item | Unit | Index | Test Methods |

| Exterior | – | yellow transparent liquid | GB/T 8237.6.1.1 |

| Viscosity | 25℃, cP | 350-450 | GB/T 7193.4.1 |

| Contain | % | 56.0-60.0 | GB/T 2895 |

| SPI-GT | min | 8.0-14.0 | GB/T 7193.4.4 |

| SPI-CT | min | 10.0-17.0 | GB/T 7193.4.4 |

| SPI-PET | ℃ | 210-240 | GB/T 7193.4.4 |

The curing system used when testing the gel time is: the curing agent is ENOX BPO-50F: 2%.

The physical properties of the cast body (for reference only):

| Item | Unit | Measured Value | Test Methods |

| Tensile Strength | MPa | 70 | GB/T 2568 |

| Tensile modulus | MPa | 3149 | GB/T 2568 |

| elongation at break | % | 2.82 | GB/T 2568 |

| Bending strength | MPa | 118 | GB/T 2570 |

| Flexural modulus | MPa | 3287 | GB/T 2570 |

| Impact toughness | KJ/m2 | 6.4 | GB/T 2571 |

| Barcol hardness | — | 45 | GB/T 3854 |

| Heat distortion temperature | ℃ | 108 | GB/T 1634 |

Note:

The casting body production method is performed according to GB/T 8237-2005, and the curing system is: 6% Co-Naph: 0.2%, AKZO LPT: 1.5%;

The post-curing system of the casting body is: room temperature (24h) +60C (3h) +100C (2h).

The recommended ratio (weight ratio) is:

| Season | Resin/ENOX BPO-50F/ENOX TBPB |

| Summer | 100/0.5~1.0/1.0~2.0 |

| Winter | 100/1.0~2.0/1.0~2.0 |

Note:

The extrusion solidifying agent mostly uses medium-high temperature composite solidifying agents, that is, BPO and TBPB are used together. In actual use, it needs to be adjusted according to different mold temperatures, extrusion speeds, product thickness diameters, and seasonal temperatures.

Benzoyl peroxide ENOX BPO-50F is a medium-temperature peroxide curing agent product from ENOX; tert-butyl perbenzoate ENOX TBPB is a high- temperature peroxide curing agent product from ENOX.

Handling and Storage:

This resin contains ingredients which could be harmful if mishandled. Contact with skin and eyes should be a voided and necessary protective equipment and clothing should be worn.

Drums – It is highly recommended that all material is stored at stable temperatures below 25℃ (77℉). Avoid exposure to heat sources such as dir ect sunlight or steam pipes. To avoid contamination of product with water, do not store outdoors. Keep sealed to prevent moisture pick-up and monomer loss. Rotate stock.

We provide small samples free of charge, but you will need to cover the shipping costs.

We have our own technical department. After you test the sample, please provide us with your detailed requirements. We can adjust the resin accordingly to enhance the properties of your finished products.

Honestly, it depends on the quantity. We will do our best to create a production plan based on your estimated time of arrival (ETA).

For the first trial order, we require 100% payment upfront. For subsequent orders, we ask for 30% payment in advance and 70% payment after the buyer receives the B/L copy. We also accept L/C if needed.