Principal Properties & Application:

ALITA L-5016 is a Low Profile (LP) additive specifically designed for Class-A surface SMC/BMC molding applications. Its exceptionally low viscosity and excellent shrinkage control enable the production of final products with precise shrinkage rates, including zero or even negative values. This makes it an ideal solution for compression molding of products requiring high surface quality and accurate dimensional stability. Additionally, ALITA L-5016 exhibits outstanding heat resistance, water resistance, and weather resistance, meeting the demanding requirements of specialized molding products.

Specifications of liquid resin:

| Item | Standard Requirements | Unit | Test Method |

| Appearance | clean | – | – |

| Acid value | 4-8 | mgKOH/g | GB/T 2895-2008 |

| Viscosity,25℃ | 1.4-1.8 | Pa.s | GB/T 7193-2008 |

| Solid content | 38-43 | % | GB/T 7193-2008 |

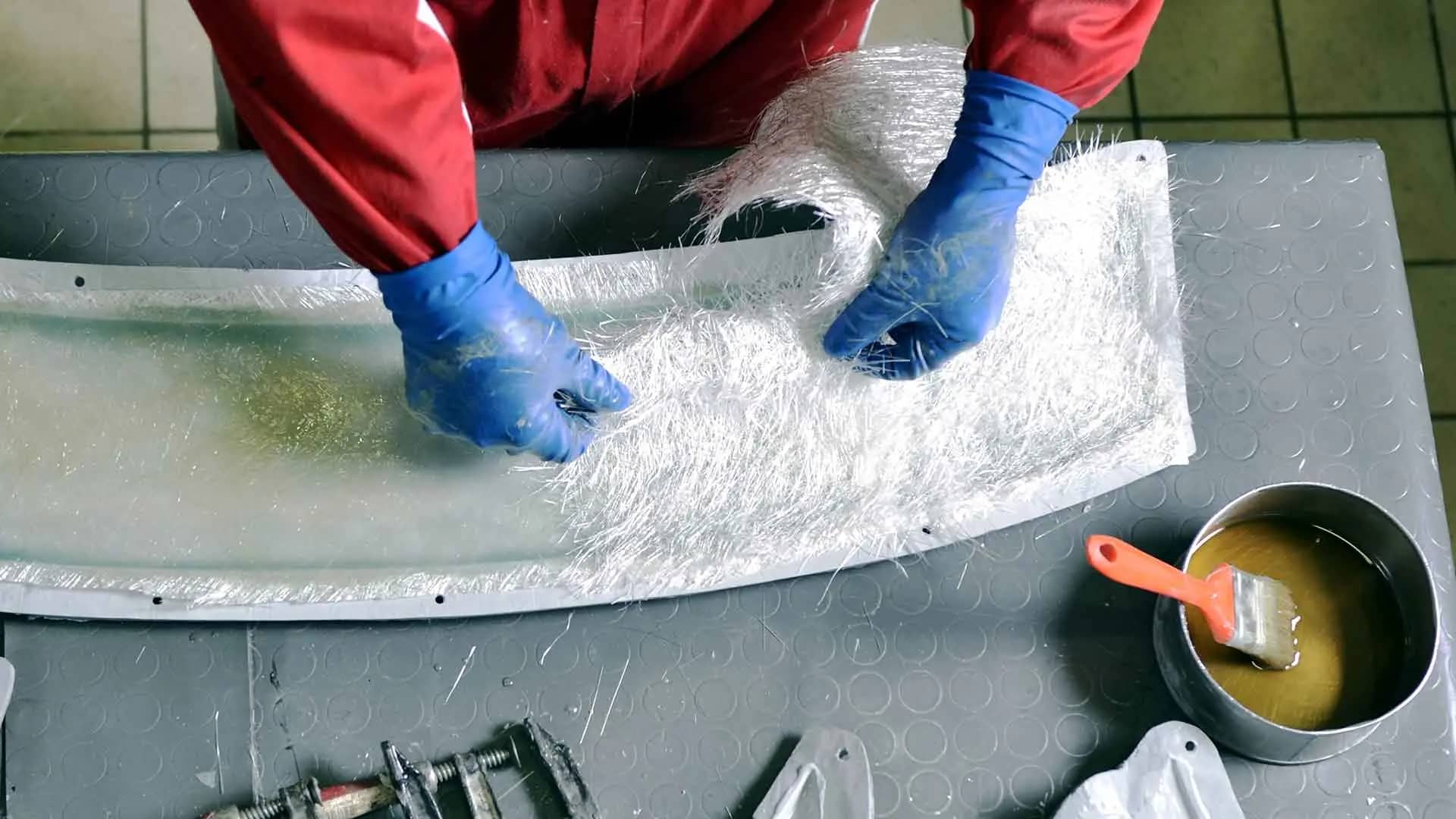

Physical Properties of SMC Moulded Plastic (for reference only):

| Item | Typical Values | Unit | Test Method |

| Density | – | g/cm³ | – |

| Fiber Glass Content | 30 | % | – |

| Shrinkage Rate | -0.06 | % | DIN 53464 |

| Flexural Strength | 175 | MPa | ISO 178 |

| Flexural Modulus | 10000 | MPa | ISO 178 |

| Tensile Strength | 80 | MPa | ISO 527-2 |

| Tensile Modulus | 9000 | MPa | ISO 527-2 |

| Elongation at Break | 3.1 | % | ISO 527-2 |

Usage instructions:

-

- ALITA L-5016 is typically used in conjunction with ALITA 1596G for the production of low shrinkage molded plastics. Generally, the recommended ratio of ALITA L-5016 to ALITA 1596G is 50:50, but it can be adjusted as per specific requirements.

-

- The molding conditions are set at a temperature of 140~160°C and pressure of 50~100kg/cm². Depending on the desired dimensions of the final product, it is possible to add 300ppm~600ppm of p-Benzoquinone to the formulation (calculated based on the total amount of resin and low profile (LP) additive).

Handling and Storage:

This resin contains ingredients which could be harmful if mishandled. Contact with skin and eyes should be avoided and necessary protective equipment and clothing should be worn.

Drums – It is highly recommended that all material is stored at stable temperatures below 25°C (77°F). Avoid exposure to heat sources such as direct sunlight or steam pipes. To avoid contamination of product with water, do not store outdoors. Keep sealed to prevent moisture pick-up and monomer loss. Rotate stock.

We provide small samples free of charge, but you will need to cover the shipping costs.

We have our own technical department. After you test the sample, please provide us with your detailed requirements. We can adjust the resin accordingly to enhance the properties of your finished products.

Honestly, it depends on the quantity. We will do our best to create a production plan based on your estimated time of arrival (ETA).

For the first trial order, we require 100% payment upfront. For subsequent orders, we ask for 30% payment in advance and 70% payment after the buyer receives the B/L copy. We also accept L/C if needed.