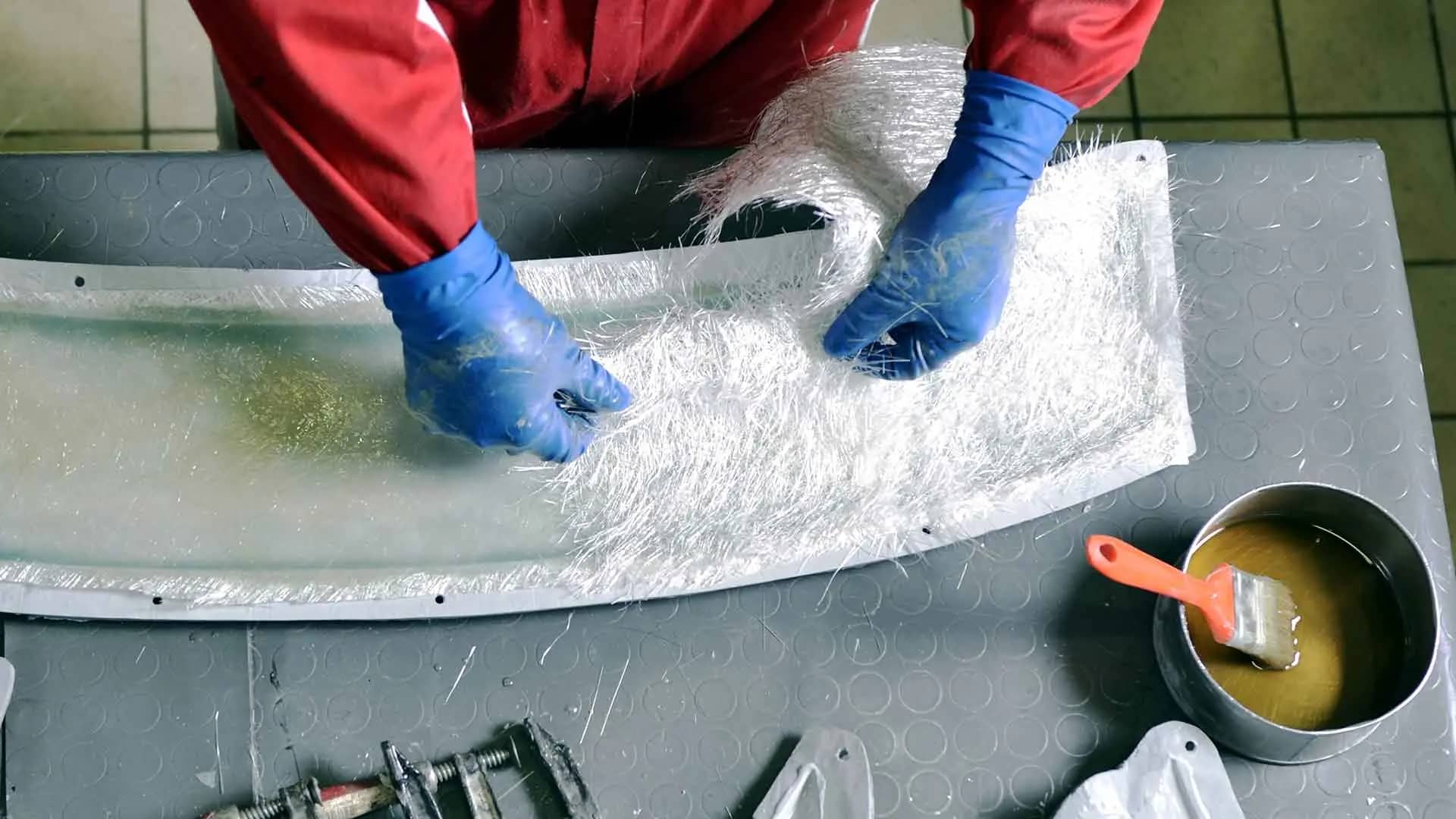

Talc powder plays an essential role in FRP composites, providing significant benefits like high purity, moisture resistance, and an extended shelf life. By adding talc powder, the natural shrinkage of the resin in FRP can be effectively reduced, as it helps lower the heat generated by the resin, leading to minimized deformation and shrinkage. Its applications are extensive, including use as FRP filler material, in FRP molding, and as fiberglass filler material.

Talc Powder Specification List

| SiO2 | 35%min | 35.25% | ||

| MgO | 30%min | 30.25% | ||

| Fe2O3 | 0.3%max | 0.22% | ||

| Al2O3 | 0.25%mx | 0.23% | ||

| Moisture | 0.5%max | 0.3% | ||

| Whiteness | 90%min | 90.2% | ||

| CaO | 1.5%max | 1.3% | ||

| L.O.I. | 25%max | 24.5% | ||

| PHYSICAL | NO ODOUR,NO TASTER,NO SANDY GRAINS,SMOOT | |||

| 325mesh 45um Passing Through (%) | 98%min | 98.5% | ||

We provide small samples free of charge, but you will need to cover the shipping costs.

We have our own technical department. After you test the sample, please provide us with your detailed requirements. We can adjust the resin accordingly to enhance the properties of your finished products.

Honestly, it depends on the quantity. We will do our best to create a production plan based on your estimated time of arrival (ETA).

For the first trial order, we require 100% payment upfront. For subsequent orders, we ask for 30% payment in advance and 70% payment after the buyer receives the B/L copy. We also accept L/C if needed.